Our Rotary Vane pumps feature self-compensating sliding-vanes which maintain design head and flow capacities for extended operating life. This high pressure pump range is suitable for thin non-lubricating liquids and / or high differential pressures. The RV pumps are capable of self-priming from a dry start.

ROTARY VANE PUMPS

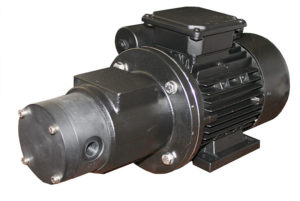

Machined Billet Rotary Vane Seal-less Mag-Drive Pumps (superseding the WMDAV) are built for high system pressures and special alloy requirements. All WMPA pumps are equipped with zero leakage magnetic couplings to meet the latest toxic emissions regulations. The absence of mechanical seals eliminates costly pump maintenance, lost production time and process contamination. The WMPA pumps feature self - compensating sliding-vanes which maintain design head and flow capacities for extended operating life. The WMPA pumps are suitable for thin non-lubricating liquids and/or high differential pressures. The WMPA pumps are capable of dry self-priming.

Machined Billet Rotary Vane Seal-less Mag-Drive Pumps (superseding the WMDAV) are built for high system pressures and special alloy requirements. All WMPA pumps are equipped with zero leakage magnetic couplings to meet the latest toxic emissions regulations. The absence of mechanical seals eliminates costly pump maintenance, lost production time and process contamination. The WMPA pumps feature self - compensating sliding-vanes which maintain design head and flow capacities for extended operating life. The WMPA pumps are suitable for thin non-lubricating liquids and/or high differential pressures. The WMPA pumps are capable of dry self-priming.

Features

- Self-priming and can run dry without damage

- No gears to wear or metal to metal contact, low internal slip

- Capable of proportioning with variable speed drives, turn-down ratios depend upon differential head requirements

- Heavy duty alloy containment shell for added safety

- Replaceable carbon cartridges-low maintenance costs

- High Torque magnets for direct starting motors

Technical Data

- Flow: .1-11 GPM (22-2500 m³/H)

- Head: To 180 psig (12 bar)

- Temperature Ratings: To 450°F (to 232°C)

- Pressure ratings: 7250 PSIG (500 Bar)

Materials

- AISI SS-316 Stainless Steel, Incoloy-825, Hastelloy-B or C-276

machined thermoplastic self-priming rotary vane seal-less Mag-drive pumps (MP Series) are positive displacement pumps intended for low-flow / high head applications, high-pressure systems or where metering is required. CNC machined from solid Simona polypropylene or polyvinylidene fluoride (PVDF, Kynar), WMRP Machined In-Line pumps are extremely resistance to internal or external corrosion, permeation and migration of solvents and corrosive. WMRP Machined In-Line pumps can handle pressurized applications and are capable of dry starting. Zero-leakage operation ensures maximum safety and full compliance with toxic emissions regulations.

machined thermoplastic self-priming rotary vane seal-less Mag-drive pumps (MP Series) are positive displacement pumps intended for low-flow / high head applications, high-pressure systems or where metering is required. CNC machined from solid Simona polypropylene or polyvinylidene fluoride (PVDF, Kynar), WMRP Machined In-Line pumps are extremely resistance to internal or external corrosion, permeation and migration of solvents and corrosive. WMRP Machined In-Line pumps can handle pressurized applications and are capable of dry starting. Zero-leakage operation ensures maximum safety and full compliance with toxic emissions regulations.

Features

- Self-Priming and can run dry without damage

- No gears to wear or metal to metal contact, low internal slip

- Capable of proportioning with variable speed drives, turn-down ratios depend upon differential head requirements

- Replaceable carbon cartridge-low maintenance costs

- High torque magnets for direct starting motors

- All non-metallic wetted components

Technical Data

- Flow: .1-11 GPM (22-2500 m³/H)

- Head: To 50 psig (3.4 bar)

- Temperature Ratings: To 200°F (to 95°C)

- System Pressures: 180 PSIG (7 Bar)

Materials

- PP, PVDF/Kynar, ETFE

Features

- High-head, low-flow functionality minimizes bypass requirements

- Does not need priming and can run dry without damage

- Heavy-duty alloy casing and containment shell

- No gears to wear or metal-to-metal shearing, low internal slip

- Capable of proportional operation with variable-speed drive component

- Chemical resistant carbon or silicon carbide sleeve bearings

- Quick-change rear cartridge assembly allows ease of servicing and reduces maintenance costs

- High-torque magnetic couplings in the magnetic vane pump eliminate need for soft-starting motors

- All ports are raised-face 150 lb. or 300 lb. ANSI flanges (600 lb. and 900 lb. are also available)