things one cannot see …

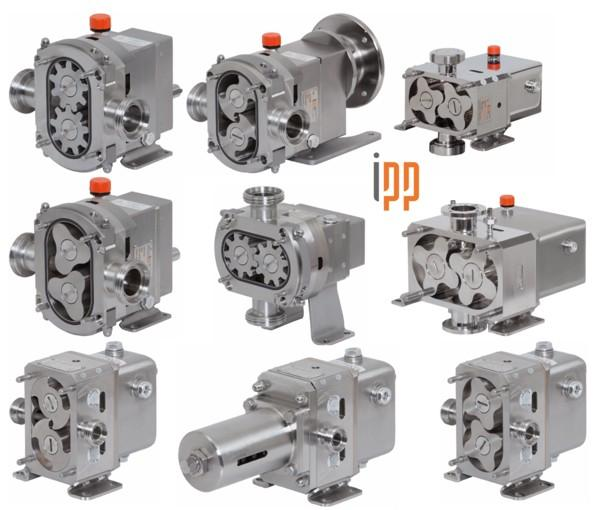

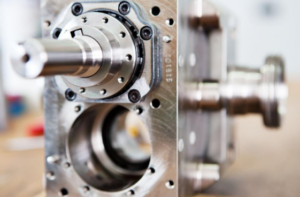

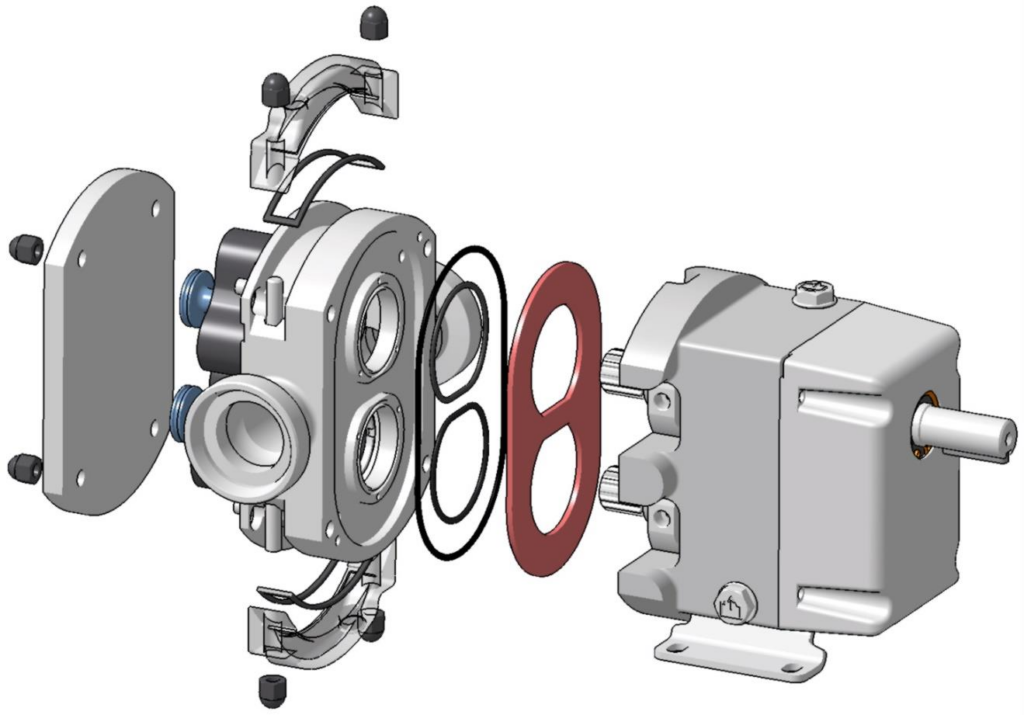

iPP Pumps are machined out of a solid block (forged) Stainless Steel material

Higher differential pressures than comparable rotary lobe pumps of other manufacturers (longer service life – reliability)

Insensibility to temperature variation within the common temperature changes during CIP/SIP-procedures – pump can run during CIP/SIP.

High precision in design and manufacturing for all of our pumps

Simple operation and maintenance results in less errors and downtime

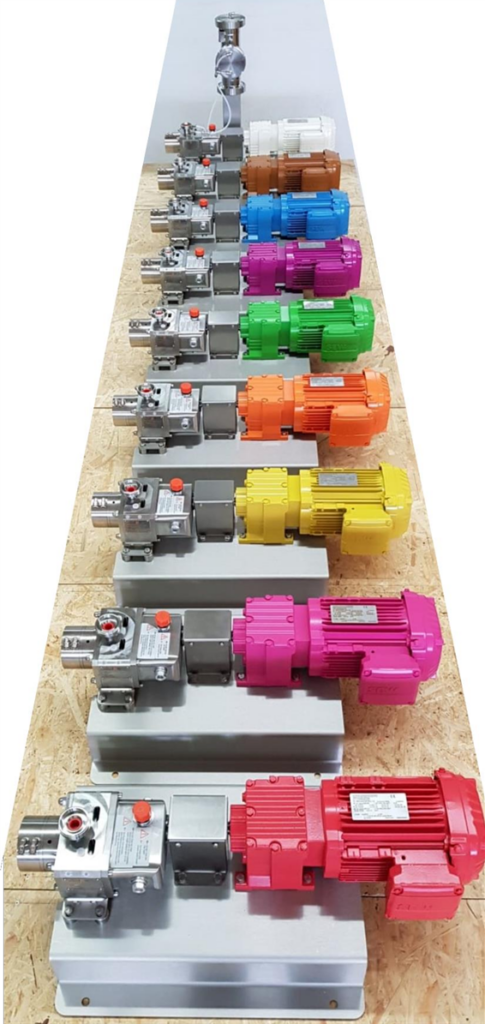

IPP Lobe Pumps – Innovation by Design

iPP-LOBE PUMPS INNOVATION BY DESIGN

- Food Industry: Sugar, Starch, Mashed Potatoes, Lard, Vitamins, Glucose Syrup, Coffee Essence, Lecithin, Glycerin, Baby Food

- Confectionery, Candy: Chocolate, Marzipan Paste, Liquid Sugar, Fudge, Jam, Marmalade, Honey, Fruit Preparations, Sugar Mixtures, Starch, Cocoa Butter

- Bakery Products: Dough, Shortening, Stuffing, Coatings

- Bio Technology: Vaccine, Dilutions, Cell Cultures, Ultra-Filtrates, Cross Flow• Filtration, Blood, Blood Plasma

- Chemicals: Flavoring Compounds, Acid, Base, Varnish, Paints, Polymers, Resin, Wax, Solvents, Glue, Adhesives, Binders, Latex, Glycerin, Lecithin, Hydro Carbons

- Condiments / Food Stuff: Eggs, Mayonnaise, Dressings, Sauces, Soups, Stews, Ketchup, Mustard, Tomato Puree

- Meat Products: Sausage Meat, Minced Meat, Spice, Gelatin

- Beverages: Alcohol, Beer, Yeast, Fruit Juice, Lemonade, Mineral Water, Fruit Juice Concentrate, Liqueur, Wine, Syrup

- Cosmetics: Shampoo, Shower Gel, Soaps, Lotions, Creme, Lip Stick, Suntan Oil, Perfume, Gels, Tooth Paste

- Dairy: Curd Cheese, Yogurt, Pudding, Cheese, Butter, Whey, Cream, Soured Milk, Margarine

- Pharmaceuticals: Raw Materials, Ointments, Sera, Cough Syrup, Plant Essences

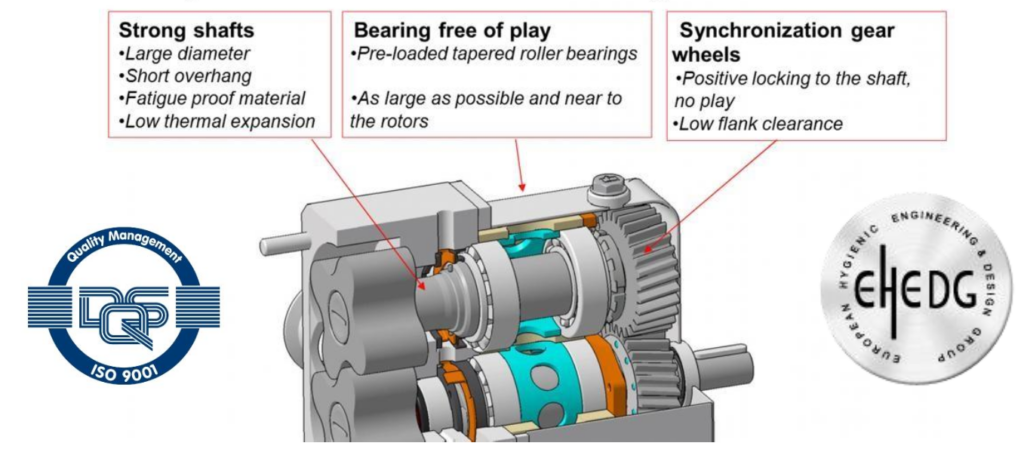

IPP DESIGN minimizes the following:

-

Bending of the shaft due to differential pressure

-

Differential temperatures putting strain on single components

(even when made from same material - rotating and fixed parts)

-

Deformation and elastic deformation of the synchronization gearbox

due to short term loads due to pressure spike

Requirements for Contactless Running

- Machined out of a solid block of forged Stainless Steel iPP maximizes design criteria to bring you a pump that is very much different from what is in the market today.

- All FDA approved materials and designed to meet EHEDG.

- iPP Lobe Pumps are designed to handle any hygienic challenge.

- Bearing location, shaft configuration and the overall design concept of the gear box in the iPP Premium Lobe Pump contribute, by design, to a very stiff pump and therefore minimal bending or deformation of the pump and the shafts under load. (guaranteed NO touching at design pressure of pump)

- Less bending of the shafts means in design terms that the “GAP” (physical tolerance between the rotors and the casing) can be made smaller i.e. the volumetric efficiency of the pump will get better plus the pump can withstand greater pressures and pump loads. This means that all models can be operated with high volumetric efficiency (small “gap”) and without the fear of contact between rotor and casing.

- Differential pressures of up to 600 psi (40 bar) at cold commissioning and up to 1200 psi (80 bar) with product can be reached. Corresponding pressure resistant housing parts and flanges are chosen in accordance with those requirements.

iPP Lobe Pumps do not use Shims to assemble the pumps.

This is easier on Maintenance and prevents mistakes at assembly !

It also reduces error and human influences do to too much or too little shimming.

iPP Lobe Pumps do not use Shims to assemble the pumps.

This is easier on Maintenance and prevents mistakes at assembly !

It also reduces error and human influences do to too much or too little shimming.

Less guess work in maintenance = higher reliability !

These design changes and characteristics make the iPP Premium Lobe Pump the new standard in the industry and iPP Pumps the leader through design and innovation. The iPP Premium Lobe Pump stands out significantly from any other rotary lobe pump on the market today. These innovations are supported through scientifically based design and production programs (know-how) in order to achieve maximum precision, performance and safety in all of our products.

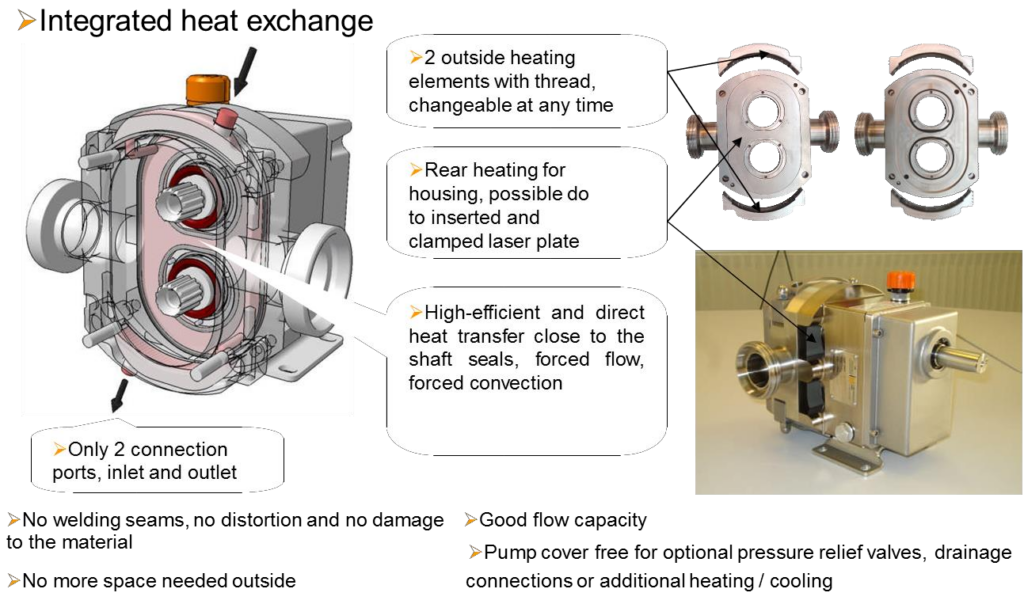

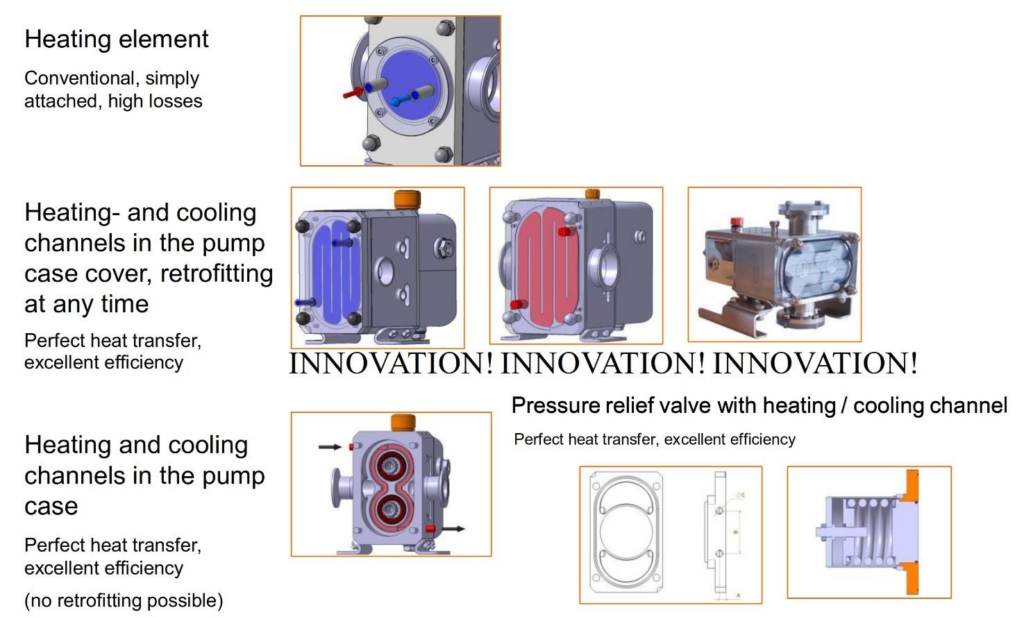

Heat where it counts

Heat where it counts

- Heat where it is most needed i.e. Mechanical Seals

- Heat if product crystallizes when cold

- Heat to prevent product from "sticking" to mechanical seal faces

- Heat to prevent premature Seal Failure (reliability)

Heger Pumps, Inc. – iPP – 24 h – hotline +1 (562) 989-5432 or [email protected]