IST – BLAGDON AOD PUMPS

AIR OPERATED DIAPHRAGM PUMPS

AIR – DIAPHRAGM PUMPS FOR INDUSTRIAL APPLICATIONS

SIZE: 1 /2 inch to 4 inch

Materials: in Cast Iron, Aluminum, Stainless Steel and Hastelloy C, with Buna N, EPDM, Viton or Teflon Diaphragms

Filter press applications, pump out, transfer pumps etc.

AIR – DIAPHRAGM PUMPS FOR INDUSTRIAL APPLICATIONS

SIZE: 1 /2 inch to 4 inch

Materials: in Cast Iron, Aluminum, Stainless Steel and Hastelloy C, with Buna N, EPDM, Viton or Teflon Diaphragms

Filter press applications, pump out, transfer pumps etc.

AIR – DIAPHRAGM PUMPS FOR SPECIAL APPLICATIONS

Materials: in PP, PE, KALREZ, with diaphragms made from Hytrel, EPDM, Viton or Teflon

AIR – DIAPHRAGM PUMPS FOR SPECIAL APPLICATIONS

Materials: in PP, PE, KALREZ, with diaphragms made from Hytrel, EPDM, Viton or Teflon

MICRO AOD PUMPS

the smallest pneumatic pumps for the chemical industry MAX FLOW 1.32 gpm (5 l/min) MAX PRESSURE 120 psi (8 bar)

- Patented stall protection pneumatic circuit

- Works with non-lubricated air

- Self priming

- Possibility of adjusting the pumping speed

- Versatility of use

- Broad choice of materials that are compatible with the fluid to be pumped

- Idles without damage

- Particularly suitable for heavy duty applications

- High performance• High power and sturdiness

- Available with NPT fittings (on request)

- Suitable for pumping high viscosity fluids

- Can be set up in tight spaces

- Atex zone 1 (on request) - Atex zone 2 standard

- Can be ceiling-mounted

- Patented stall protection pneumatic circuit

- Works with non-lubricated air

- Self priming

- Possibility of adjusting the pumping speed

- Versatility of use

- Broad choice of materials that are compatible with the fluid to be pumped

- Idles without damage

- Particularly suitable for heavy duty applications

- High performance• High power and sturdiness

- Available with NPT fittings (on request)

- Suitable for pumping high viscosity fluids

- Can be set up in tight spaces

- Atex zone 1 (on request) - Atex zone 2 standard

- Can be ceiling-mounted

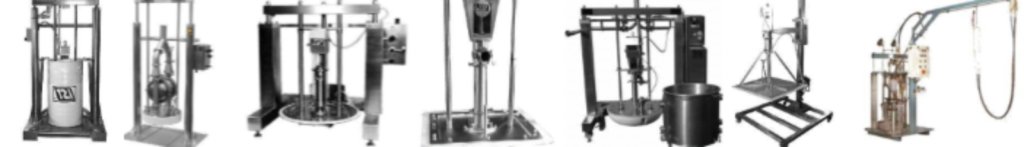

AIR OPERATED PISTON PUMPS & UNLOADER SYSTEMS

High Pressure Air Operated Extrusion and Piston Pumps (120 psi (8 bar) air)

Flows from : 49 cm3/stroke to 600 cm3/stroke Pressure : from 50 psi to 8,300 psi (3 bar to 560 bar) (based on 120 psi (8 bar) air pressure max)

100 ml to 1600 Liter cartridges, buckets, barrels etc.

Need to empty a cartridge, tin, bucket or barrel ? We will help you make the emptying process easy. With our accessories, we make barrel changes easy. Our Systems can handle viscosities from 80,000 to 5,000,000 mPas. We can integrate the container/barrel unloading system into a dosing application.we will empty your container/barrel to a residue of under 1% !contact us at [email protected] with your application.

Heger Pumps, Inc. 24 h – hotline +1 (562) 989-5432 or [email protected]