HIGH SHEAR INLINE MIXERS

HOMOGENIZATION – MIXING – DISPERSION – DISINTEGRATION – EMULSIFICATION –

DISSOLVING - REACTING - GRINDING

HIGH SHEAR INLINE MIXER - SANITARY AND LAB SERIES

Supraton® inline homogenizers in the Sanitary version show the following features for use in hygiene conditions:

HIGH SHEAR INLINE MIXER - SANITARY AND LAB SERIES

Supraton® inline homogenizers in the Sanitary version show the following features for use in hygiene conditions:

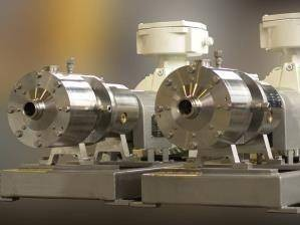

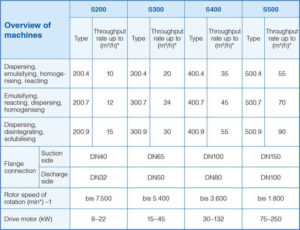

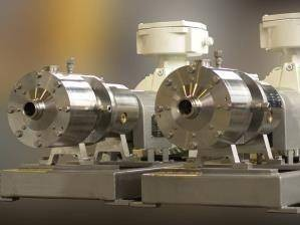

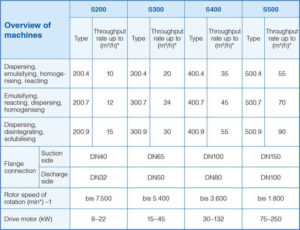

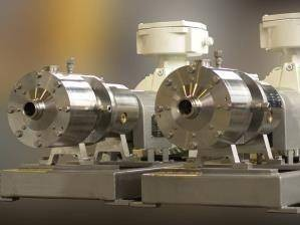

HIGH SHEAR INLINE MIXERS - S-SERIES MACHINES

The Supraton® S-series the right machine for first-class homogenization. Small product quantities can be introduced directly into the shearing and mixing zone by means of stator injection so that optimum homogenization is guaranteed. High Shear machines that deliver.

HIGH SHEAR INLINE MIXERS - S-SERIES MACHINES

The Supraton® S-series the right machine for first-class homogenization. Small product quantities can be introduced directly into the shearing and mixing zone by means of stator injection so that optimum homogenization is guaranteed. High Shear machines that deliver.

BITUMEN HOMOGENIZER – ASPHALT EMULSIONS

The Supraton® Bitumen Homogenizer are designed for the production of polymer modified bitumen. Due to their special design the processing of polymers in bitumen is very efficient, especially in the form of pellets. The machines have been running successfully for many decades and are based on a three-stage rotor/stator tool. The features of the Supraton® bitumen homogenizers 349-5, 449-5 and 549-5.03 are unique:

BITUMEN HOMOGENIZER – ASPHALT EMULSIONS

The Supraton® Bitumen Homogenizer are designed for the production of polymer modified bitumen. Due to their special design the processing of polymers in bitumen is very efficient, especially in the form of pellets. The machines have been running successfully for many decades and are based on a three-stage rotor/stator tool. The features of the Supraton® bitumen homogenizers 349-5, 449-5 and 549-5.03 are unique:

HIGH SHEAR INLINE MIXER - SANITARY AND LAB SERIES

Supraton® inline homogenizers in the Sanitary version show the following features for use in hygiene conditions:

HIGH SHEAR INLINE MIXER - SANITARY AND LAB SERIES

Supraton® inline homogenizers in the Sanitary version show the following features for use in hygiene conditions:

-

- NO deposits due to 4-stage rotor/stator tool of seamless , monolithic design

- Freely select-able sense of rotation of the tools due to their symmetrical structure and therefore utilization of both tool flanks witch leads to an increase in the service life of the chamber tool set

HIGH SHEAR INLINE MIXERS - S-SERIES MACHINES

The Supraton® S-series the right machine for first-class homogenization. Small product quantities can be introduced directly into the shearing and mixing zone by means of stator injection so that optimum homogenization is guaranteed. High Shear machines that deliver.

HIGH SHEAR INLINE MIXERS - S-SERIES MACHINES

The Supraton® S-series the right machine for first-class homogenization. Small product quantities can be introduced directly into the shearing and mixing zone by means of stator injection so that optimum homogenization is guaranteed. High Shear machines that deliver.

-

- External oil-cooled bearing system for high driving power and temperature resistance in continuous operation.

-

- High-quality materials, from duplex stainless steel to metal/ceramic combinations, ensure increased wear resistance.

-

- The Supraton® S-series is structured axisymmetrically and is thus suitable for both senses of rotation. In that way, both tooth flanks can be used in the event of wear.

-

- tool geometries for efficiency and performance optimisation of rotor/stator systems.

- Excellent rotor stability, even in the case of extremely high viscosities and rotation speed, ensures a high degree of reproducibility as well as a reliable scale-up capability.

-

- Product viscosities up to 200,000 cP

-

- Throughput rates depending on process to 440 gpm (100 m³/ hr) (larger machines are available)

- Particle sizes up to 0.2 inch (5 mm)

-

- Temperatures up to 460 deg F (240 deg C)

-

- pressures to 300 psi (20 bar) (higher pressures available)

BITUMEN HOMOGENIZER – ASPHALT EMULSIONS

The Supraton® Bitumen Homogenizer are designed for the production of polymer modified bitumen. Due to their special design the processing of polymers in bitumen is very efficient, especially in the form of pellets. The machines have been running successfully for many decades and are based on a three-stage rotor/stator tool. The features of the Supraton® bitumen homogenizers 349-5, 449-5 and 549-5.03 are unique:

BITUMEN HOMOGENIZER – ASPHALT EMULSIONS

The Supraton® Bitumen Homogenizer are designed for the production of polymer modified bitumen. Due to their special design the processing of polymers in bitumen is very efficient, especially in the form of pellets. The machines have been running successfully for many decades and are based on a three-stage rotor/stator tool. The features of the Supraton® bitumen homogenizers 349-5, 449-5 and 549-5.03 are unique:

-

- Special tool geometry for different sorts of bitumen, particularly advantageous in processes with one flow and high polymer concentration

-

- Three-stage rotor/stator tool for the intrusion, shearing/ comminution and dispersion especially of polymers in the form of pellets and similar substances

-

- Adjustment of the gap for energy-saving starts by hydraulic and axial displacements of the shaft

-

- The standard adjustment open/close for start, shut down and pump over can be completed with a step-less adjustment

-

- the strong pumping effect of the machine supports the supply pump and supersedes it most of the time

HIGH SHEAR INLINE MIXER - SANITARY AND LAB SERIES

-

- NO deposits due to 4-stage rotor/stator tool of seamless , monolithic design

- Freely select-able sense of rotation of the tools due to their symmetrical structure and therefore utilization of both tool flanks witch leads to an increase in the service life of the chamber tool set

HIGH SHEAR INLINE MIXERS - S-SERIES MACHINES

The Supraton® S-series the right machine for first-class homogenization. Small product quantities can be introduced directly into the shearing and mixing zone by means of stator injection so that optimum homogenization is guaranteed. High Shear machines that deliver.

The Supraton® S-series the right machine for first-class homogenization. Small product quantities can be introduced directly into the shearing and mixing zone by means of stator injection so that optimum homogenization is guaranteed. High Shear machines that deliver.

The Supraton® S-series the right machine for first-class homogenization. Small product quantities can be introduced directly into the shearing and mixing zone by means of stator injection so that optimum homogenization is guaranteed. High Shear machines that deliver.

The Supraton® S-series the right machine for first-class homogenization. Small product quantities can be introduced directly into the shearing and mixing zone by means of stator injection so that optimum homogenization is guaranteed. High Shear machines that deliver.

-

- External oil-cooled bearing system for high driving power and temperature resistance in continuous operation.

-

- High-quality materials, from duplex stainless steel to metal/ceramic combinations, ensure increased wear resistance.

-

- The Supraton® S-series is structured axisymmetrically and is thus suitable for both senses of rotation. In that way, both tooth flanks can be used in the event of wear.

-

- tool geometries for efficiency and performance optimisation of rotor/stator systems.

-

- Excellent rotor stability, even in the case of extremely high viscosities and rotation speed, ensures a high degree of reproducibility as well as a reliable scale-up capability.

-

-

- Product viscosities up to 200,000 cP

-

- Throughput rates depending on process to 440 gpm (100 m³/ hr) (larger machines are available)

-

- Particle sizes up to 0.2 inch (5 mm)

-

- Temperatures up to 460 deg F (240 deg C)

-

- pressures to 300 psi (20 bar) (higher pressures available)

-

BITUMEN HOMOGENIZER – ASPHALT EMULSIONS

-

- Special tool geometry for different sorts of bitumen, particularly advantageous in processes with one flow and high polymer concentration

-

- Three-stage rotor/stator tool for the intrusion, shearing/ comminution and dispersion especially of polymers in the form of pellets and similar substances

-

- Adjustment of the gap for energy-saving starts by hydraulic and axial displacements of the shaft

-

- The standard adjustment open/close for start, shut down and pump over can be completed with a step-less adjustment

-

- the strong pumping effect of the machine supports the supply pump and supersedes it most of the time

Heger Pumps, Inc. 24 h – hotline +1 (562) 989-5432 or [email protected]