CENTRIFUGAL PUMPS

SUBMERSIBLE PUMPS - PORTABLE ELECTRIC TO STATIONARY PUMPS

APPLICATIONS: Wastewater, Sump Pumps, Sewage Lift, Industrial Waste, Power Plants, De watering, Tunneling, Mining, Marine-Aquaculture etc.

Available in cast iron, 304 SS and 316 SS with double mechanical seals

For water and dirty water applications, gray water, sump applications, liquids with abrasives and high pressure de- watering

Electrical from 115V single phase to 230/460V 3phase

SUBMERSIBLE PUMPS - PORTABLE ELECTRIC TO STATIONARY PUMPS

APPLICATIONS: Wastewater, Sump Pumps, Sewage Lift, Industrial Waste, Power Plants, De watering, Tunneling, Mining, Marine-Aquaculture etc.

Available in cast iron, 304 SS and 316 SS with double mechanical seals

For water and dirty water applications, gray water, sump applications, liquids with abrasives and high pressure de- watering

Electrical from 115V single phase to 230/460V 3phase

Flow : 10 - 2000 gpm (450 m3/h)

Discharge Head : to 310 ft (97 m)

Power : 1/2 Hp - 475 Hp (355 kW)

MATERIALS: 431 SS Shaft, 316 SS Impeller or Hardened Stainless Steel Impeller, Double Seal TC/TC

HYDRAULIC SUBMERSIBLE PUMPS

Flow : 10 - 20,000 gpm (450 m3/h)

Discharge Head : to 310 ft (97 m)

Power : 1/2 Hp - 600 Hp (450 kW)

MATERIALS: Spheroidal Cast iron, cast steel, 316 SS, specialty materials on request

Why Go Hydraulic?

- Efficient, variable speed drive saves fuel

- Easy set-up, can be operational in minutes

- No suction lift problems common with centrifugal pumps

- No electrical hazard encountered with electric submersibles

- One pump can perform tasks of several fixed speed pumps

- Many of our pumps can be bolted inline to become booster pumps

- A wide range of pumps designed to handle just about any application

- Overall size and weight is less then any comparable electric submersible

- Maintenance can be performed in the field with minimal mechanical skills

- Many different pumps can be driven from a single hydraulic power source

Model HS3CML 3" x 2" High Head Pump

Model HS3T, 3" Wastewater Pump

Specialty Pump

Specialty PumpContact us at [email protected] with your application

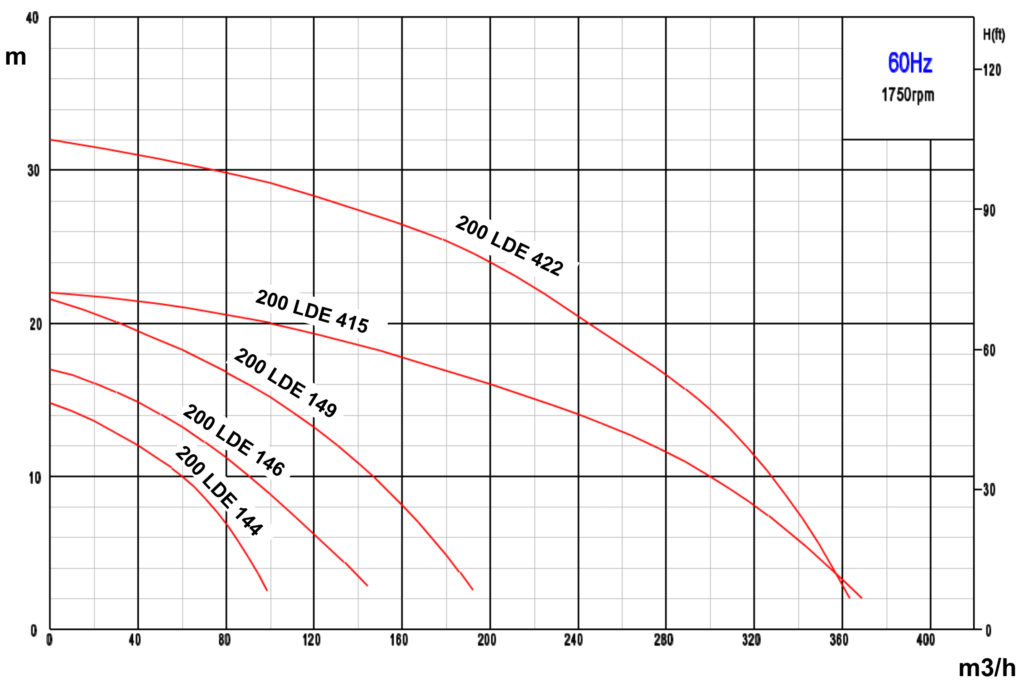

LDE SUBMERSIBLE PUMPS

PORTABLE ELECTRIC TO STATIONARY PUMPS

Dredgflow LDE type lighter duty slurry pumps designed for abrasive applications, portable, submersible high chrome submersible pump, Two Vane Semi-Open Impellers, SC/SC - SC/SC Double Mechanical Seals. High Chrome Wear Parts

APPLICATIONS: Sumps with solids, dirty water, sandy conditions

Flow : 100 - 1400 gpm (30 - 325 m3/h)

Discharge Head : to 90 ft (30 m)

Power : 5.5 Hp - 30 Hp (4 - 22 kW)

MATERIALS: 28% high chrome wear parts, 403 SS Shaft, 304 SS Hardware, Double Seal SC/SC vs SC/SC, 50 ft cable

Dredgflow LDE type lighter duty slurry pumps designed for abrasive applications, portable, submersible high chrome submersible pump, Two Vane Semi-Open Impellers, SC/SC - SC/SC Double Mechanical Seals. High Chrome Wear Parts

APPLICATIONS: Sumps with solids, dirty water, sandy conditions

Flow : 100 - 1400 gpm (30 - 325 m3/h)

Discharge Head : to 90 ft (30 m)

Power : 5.5 Hp - 30 Hp (4 - 22 kW)

MATERIALS: 28% high chrome wear parts, 403 SS Shaft, 304 SS Hardware, Double Seal SC/SC vs SC/SC, 50 ft cable

SUBMERSIBLE PUMPS - PORTABLE ELECTRIC TO STATIONARY PUMPS

Designed for abrasive applications, portable, submersible high chrome submersible pump, Two Vane Semi-Open Impellers, balanced with improved flow patterns, virtually clog-free, Double Mech Seals. High Chrome Wear Parts APPLICATIONS: Sumps with solids, dirty water, sandy conditions.

Flow : 150 - 2000 gpm (30 - 450 m3/h)

Discharge Head : to 100 ft (32 m)

Power : 2 Hp - 60 Hp (1.5 - 45 kW)

MATERIALS: 28% high chrome iron for wear parts, 403 SS Shaft, 304 SS Hardware, Double Seal SC/SC, 50 ft cable

SUBMERSIBLE PUMPS - PORTABLE ELECTRIC TO STATIONARY PUMPS

Designed for abrasive applications, portable, submersible high chrome submersible pump, Two Vane Semi-Open Impellers, balanced with improved flow patterns, virtually clog-free, Double Mech Seals. High Chrome Wear Parts APPLICATIONS: Sumps with solids, dirty water, sandy conditions.

Flow : 150 - 2000 gpm (30 - 450 m3/h)

Discharge Head : to 100 ft (32 m)

Power : 2 Hp - 60 Hp (1.5 - 45 kW)

MATERIALS: 28% high chrome iron for wear parts, 403 SS Shaft, 304 SS Hardware, Double Seal SC/SC, 50 ft cable  HYDRAULIC & ELECTRIC SUBMERSIBLE AGITATOR SLURRY PUMPS

28% HI-CHROME Dredging pumps designed for serious material handling. Available in electric and hydraulic drive these pumps will handle up to 30% solids by Volume. Hydraulic Excavators for more consistent solid flow and extra mechanical agitation are available from 20 - 50 HP, Water Jet Rings are available.

APPLICATIONS: dredging, sand & gravel, dam dredging, beach reclamation, harbor dredging, sewer cleanout, inlet basins from rivers and ocean, sump pumps for heavy solid loads, anything with solids.

Flow : 200 - 5000 gpm (30 - 450 m3/h)

Discharge Head : to 130 ft (40 m)

Power : 25 Hp - 400 Hp (20 - 300 kW)

Solid Handling : to 4.7 inch depending on pump size

MATERIALS: 28% high chrome iron, fabricated steel and cast iron support structure,

HYDRAULIC & ELECTRIC SUBMERSIBLE AGITATOR SLURRY PUMPS

28% HI-CHROME Dredging pumps designed for serious material handling. Available in electric and hydraulic drive these pumps will handle up to 30% solids by Volume. Hydraulic Excavators for more consistent solid flow and extra mechanical agitation are available from 20 - 50 HP, Water Jet Rings are available.

APPLICATIONS: dredging, sand & gravel, dam dredging, beach reclamation, harbor dredging, sewer cleanout, inlet basins from rivers and ocean, sump pumps for heavy solid loads, anything with solids.

Flow : 200 - 5000 gpm (30 - 450 m3/h)

Discharge Head : to 130 ft (40 m)

Power : 25 Hp - 400 Hp (20 - 300 kW)

Solid Handling : to 4.7 inch depending on pump size

MATERIALS: 28% high chrome iron, fabricated steel and cast iron support structure,

HORIZONTAL CENTRIFUGAL WATER & PROCESS PUMPS

APPLICATIONS: water re circulation, heating, air conditioning, heat recovery, water supply, irrigation, seawater charge pumps.

Flow : to 10120 gpm (2300 m3/h)

Discharge Head : to 310 ft (97 m)

Power : 475 Hp (355 kW)

MATERIALS: cast iron EN-GJL-250, AISI 316 stainless steel, marine bronze G-CuSn10.

HORIZONTAL / VERTICAL / INLINE WATER & PROCESS PUMPS

APPLICATIONS: water re circulation, water supply, irrigation, seawater charge pumps

Flow : to 47,500 gpm (10,800 m3/h)

Discharge Head : to 100 ft (31 m)

Power : 1,500 Hp (1,100 kW)

MATERIALS: cast iron EN-GJL-250, marine bronze G-CuSn10, Special materials on demand

MULTISTAGE CENTRIFUGAL PUMPS

Horizontal segmented electric pumps used in water plants, irrigation systems, high pressure lift systems, refrigeration, heating, snow making, high pressure cleaning, boiler feed systems etc.

Flow : to 4,800 gpm (1,100 m3/h)

Discharge Head : to 2050 ft (640 m)

Power : 850 Hp (630 kW)

MATERIALS: Cast Iron GJL-250, GJS-500, Carbon Steel, Precision Cast Stainless Steel AISI 316 or G-uSn10

FIBERGLASS REINFORCED CHEMICAL PROCESS CENTRIFUGAL PUMPS

ASME/ANSI B73.1 conform

High strength casings with 150lb. FF flanges (ISO/DIN/JIS flange configurations available) continuous strand fiberglass construction

Large capacity bearings External impeller adjustment Heavy duty shaft

Flow : to 5,000 gpm (1,140 m3/h)

Discharge Head : to 400 ft (125 m)

Temp : to 275 deg F (135 deg C)

MATERIALS: Vinyl Ester and Epoxy resins with REM Manufacturing Method HORIZONTAL "SHORT COUPLED" FIBERGLASS CHEMICAL PROCESS PUMPS

SHORT COUPLED FRP CHEMICAL PROCESS PUMPS

ASME/ANSI B73.1 conformance

High strength casings with 150lb. FF flanges (ISO/DIN/JIS flange configurations available) Continuous strand fiberglass construction

Flow : to 1,500 gpm (345 m3/h)

Discharge Head : to 400 ft (125 m)

Temp : to 250 deg F (121 deg C)

MATERIALS: Vinyl Ester and Epoxy resins with REM Manufacturing Method

MAG DRIVE FIBERGLASS CHEMICAL PROCESS PUMPS

MAG DRIVE FIBERGLASS CHEMICAL CENTRIFUGAL PUMPS

ASME/ANSI B73.1 conformance

High strength casings with 150lb. FF flanges (ISO/DIN/JIS flange configurations available) Continuous strand fiberglass construction

Flow : to 1,500 gpm (345 m3/h)

Discharge Head : to 400 ft (125 m)

Temp : to 250 deg F (121 deg C)

MATERIALS: Vinyl Ester and Epoxy resins with REM Manufacturing Method

SUBMERSIBLE FRP PUMPS

Submersible FRP Pump, problem sumps with acidic or other chemical contamination, portable applications in acidic environments

Flow : to 1,500 gpm (345 m3/h)

Discharge Head : to 400 ft (125 m)

Temp : to 250 deg F (121 deg C)

MATERIALS: Vinyl Ester and Epoxy resins with REM Manufacturing Method, FRP with 316SS-L submersible motor casing

Heger Pumps, Inc. 24 h – hotline +1 (562) 989-5432 or [email protected]

Heger Pumps, Inc. 24 h – hotline +1 (562) 989-5432 or [email protected]