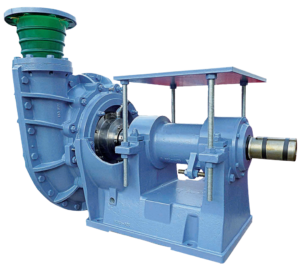

HEAVY DUTY SLURRY PUMPS

HPK-Series

Flow : 20,250 gpm (4600 m3/h)TDH single stage : 224 ft (70 m)

PH Range : 0 - 14

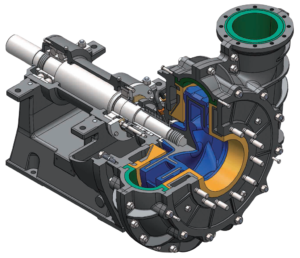

HPK Series Pumps are single-stage centrifugal pumps with easily replaceable wear parts and re-adjustable suction gap.

HPK centrifugal pumps, with elastic lining made of polyurethane polymers or rubber, metal or mineral casting, is used for abrasive and/or corrosive media with a maximum grain size of 5 mm.

Shore Hardness: from 55 - 90

Temperatures: -22 deg F to max 266 deg F (-30 deg C to max 130 deg C)

HNPK Series

Flow : 20,250 gpm (4600 m3/h)TDH single stage : 224 ft (70 m)

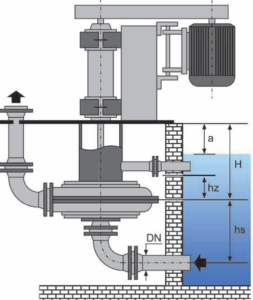

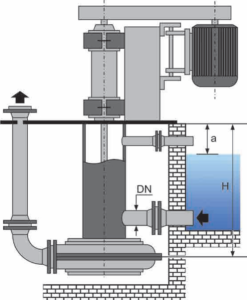

HVP SERIES VERTICAL CANTILEVER

Flow : 6,250 gpm (1400 m3/h)TDH single stage : 160 ft (50 m)

PH Range : 0 - 14

The HVP series vertical cantilever pumps benefit from our modular pump design. This allows the HVP Series to carry shared hydraulic components that are also used in our HPK, HNP-K and HNP-W series of pumps.

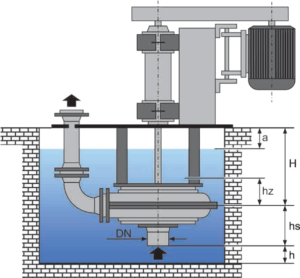

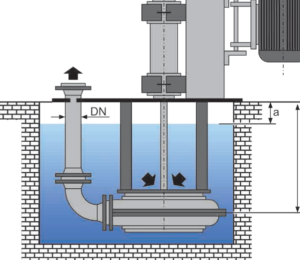

WET & DRY INSTALLATIONS

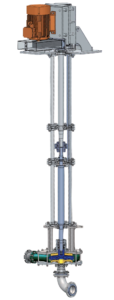

HVL VERTICAL LINE SHAFT SLURRY PUMP

Flow : 20,250 gpm (4600 m3/h) TDH single stage : 224 ft (70 m)

The HVL series line shaft pumps benefit from our modular pump design.

This allows the HVP Series to carry shared hydraulic components that are also used

in our HPK, HNP-K and HNP-W series of pumps.

Both metal and polyurethane polymer/elastomer designs are available.

WET & DRY INSTALLATIONS

contact us at info@hegerpumps.com with your applications

COMPACT SERIES HKVT / HKVT-K / HKVT-H

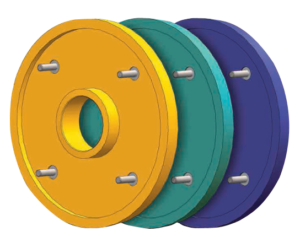

Where exposure to extremely high levels of wear is to be expected, Heger Slurry Pumps Type HKVT / HKVT-K /HKVT-H are the right choice.

Exceptional wall thicknesses account for high resistance to largest grain sizes and sharp edged stone flakes.

Features:

Where exposure to extremely high levels of wear is to be expected, Heger Slurry Pumps Type HKVT / HKVT-K /HKVT-H are the right choice.

Exceptional wall thicknesses account for high resistance to largest grain sizes and sharp edged stone flakes.

Features:

- Easy maintenance

- Adjustable wear plates for extended performance

- Closed impeller (thick cover plates, front/back)

- Wall thickness provides extreme impact resistance to large solids conveyed

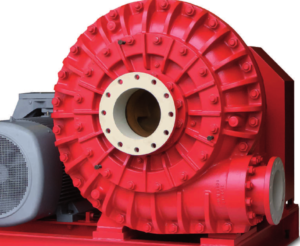

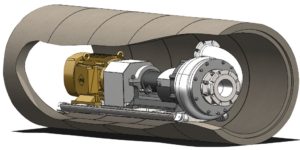

HHVS HYDRAULIC SUBMERSIBLES - SLURRY WALL APPLICATIONS

Flow : 11,000 gpm (2500 m3/h)

TDH single stage : 192 ft (60 m)

Max operating pressure : 150 psi (10 bar)

Hydraulic driven submersible pump for slurry wall (trench cutting) applications. Versatile pump for lots of different applications.

Flow : 11,000 gpm (2500 m3/h)

TDH single stage : 192 ft (60 m)

Max operating pressure : 150 psi (10 bar)

Hydraulic driven submersible pump for slurry wall (trench cutting) applications. Versatile pump for lots of different applications.

contact us at info@hegerpumps.com with your applications

ENGINEERED SLURRY SEAL APPLICATIONS

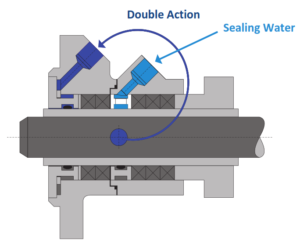

Triple Protection Gland Packing

Seal water used for :

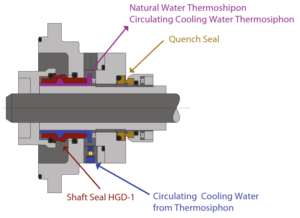

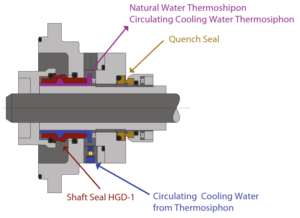

Our innovative HGD-1 is capable of handling up to 365 psi (25 bar) of pressure. the built in vortex chamber repels solids from the mechanical seal. The mechanical shaft seal is lubricated and cooled via a quench connection. Natural thermo syphon system recycles water in closed loop. We also have a pumping screw on the shaft sleeve for forced fluid circulation.

Advantages of our system :

Our innovative HGD-1 is capable of handling up to 365 psi (25 bar) of pressure. the built in vortex chamber repels solids from the mechanical seal. The mechanical shaft seal is lubricated and cooled via a quench connection. Natural thermo syphon system recycles water in closed loop. We also have a pumping screw on the shaft sleeve for forced fluid circulation.

Advantages of our system :

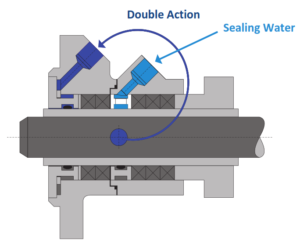

Triple Protection Gland Packing

Seal water used for :

- Sealing and cooling of multiple gland packing

- Frontline protection of complete sealing system

- Flushing of impeller’s back for minimized wear

- Simple, cost effective Heger triple protection gland packing delivers outstanding durability

- Easy installation and disassembly thanks to radial split gland housing

- Flow restriction and flow indicator for total control of sealing and lowest water consumption

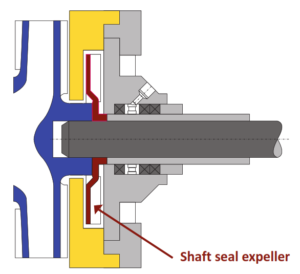

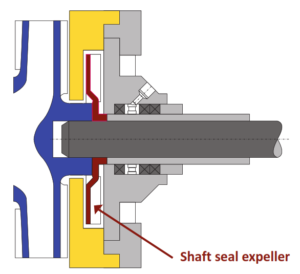

Expeller

- Expellers are available as a standard feature on most of our pumps

- The expeller is particularly useful for fine-grain heavy liquids

- Application close to the boiling point of the suspension

- minimization of seal water consumption

- Gland packing as backup during standstill

- Perfect alternative to the mechanical shaft seal for difficult uses:

- Low sealing water quality

- Under pressurized sealing water

- Under pressurized sealing water admission

Simple Mechanical Shaft Seal

We offer a large selection of mechanical seals according to the pumped medium properties and required discharge pressure. Intelligent seal designs with the seal springs safely on the atmospheric side (cutting down on abrasion/corrosion) while the wear resistant components face the slurry side.Internal Mechanical Shaft Seal with Quench

Our innovative HGD-1 is capable of handling up to 365 psi (25 bar) of pressure. the built in vortex chamber repels solids from the mechanical seal. The mechanical shaft seal is lubricated and cooled via a quench connection. Natural thermo syphon system recycles water in closed loop. We also have a pumping screw on the shaft sleeve for forced fluid circulation.

Advantages of our system :

Our innovative HGD-1 is capable of handling up to 365 psi (25 bar) of pressure. the built in vortex chamber repels solids from the mechanical seal. The mechanical shaft seal is lubricated and cooled via a quench connection. Natural thermo syphon system recycles water in closed loop. We also have a pumping screw on the shaft sleeve for forced fluid circulation.

Advantages of our system :

- No contamination of your pumped liquids

- The use of HGD-1 is also possible without a quench seal

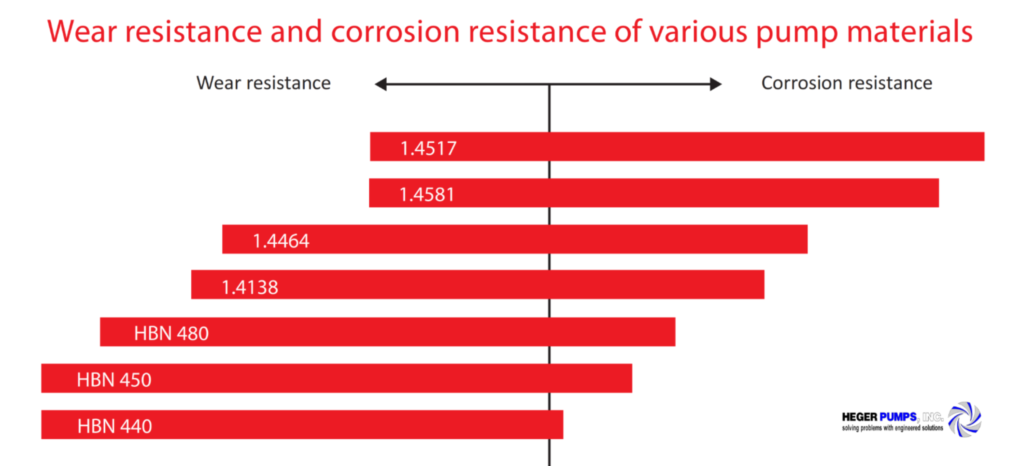

Materials for our Heavy Duty Slurry Pumps

Our wear-resistant and corrosion-resistant materials (heat-treated and duplex steels) come from decades of Foundry experience.

Heger Pumps, Inc. 24 h – hotline +1 (562) 989-5432 or info@hegerpumps.com