Self Priming Sewage Pumps

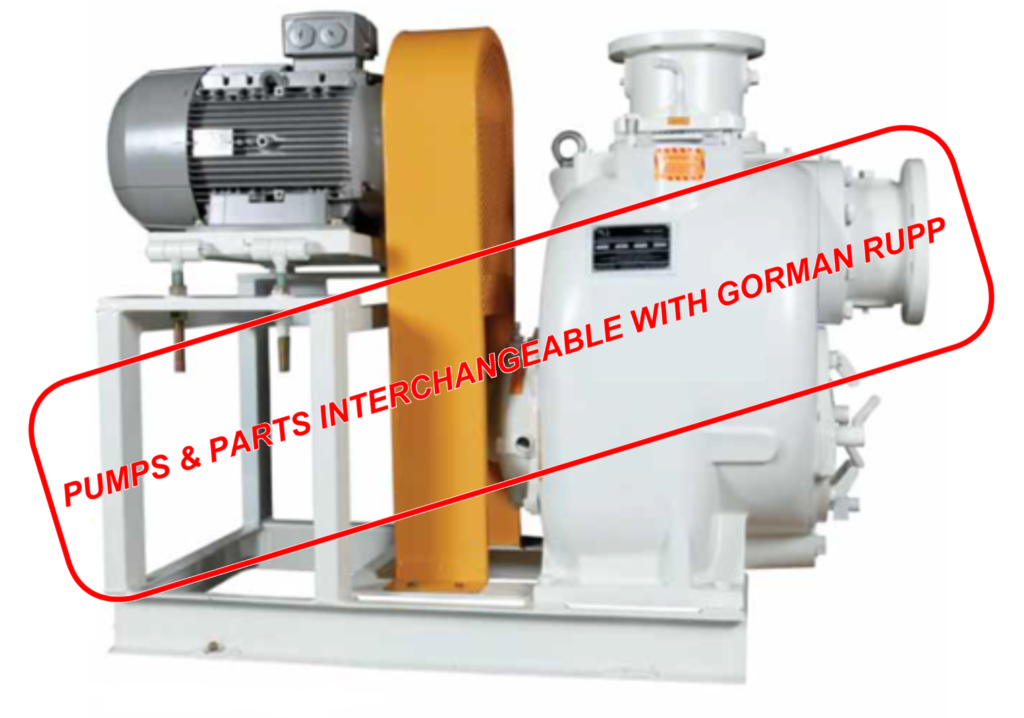

FULLY INTERCHANGEABLE PUMPS & PARTS

WITH GORMAN RUPP® Type T, U, Super T

Always searching for engineered solutions to meet the demands of our customers we committed our-self to provide the the best technology available on the market today.One of the results in looking for the latest innovations, is our Valve Set that provides the technical know how for the performance of our pumps.

Product Description

Our horizontal Self-Re-Priming centrifugal pumps, with semi-open impeller are perfect for pumping raw sewage. This type of pump is suited for all Self-Re-Priming applications i.e. pure liquids or liquids with solids in suspension. Self-Re-Priming pump applications are our forte.Our pumps range from 2” to 12” axial suction & radial discharge, with a solids handling capability of up to 1.1/4”

Always searching for engineered solutions to meet the demands of our customers we committed our-self to provide the the best technology available on the market today.One of the results in looking for the latest innovations, is our Valve Set that provides the technical know how for the performance of our pumps.

Product Description

Our horizontal Self-Re-Priming centrifugal pumps, with semi-open impeller are perfect for pumping raw sewage. This type of pump is suited for all Self-Re-Priming applications i.e. pure liquids or liquids with solids in suspension. Self-Re-Priming pump applications are our forte.Our pumps range from 2” to 12” axial suction & radial discharge, with a solids handling capability of up to 1.1/4”  An automatic air relief valve is a needed and necessary part of a raw sewage lift station installation. Featuring a diaphragm operated shut off / opening system regulated by a spring, it is set with a threaded connection and a drain back to suction.

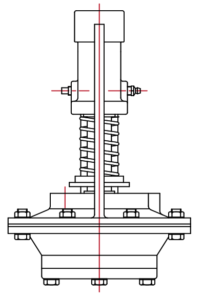

An automatic air relief valve is a needed and necessary part of a raw sewage lift station installation. Featuring a diaphragm operated shut off / opening system regulated by a spring, it is set with a threaded connection and a drain back to suction.

We have Valves for the following applications:

- Automatic Air Exhaust Valve - Self-Re-Priming Pump

- Quick-Release Check Valve - against water hammer

- Check Valve - against water hammer in sewage applications

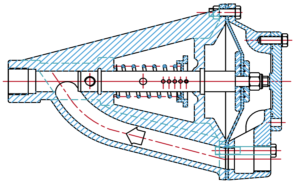

The Self-Re-Priming pump type HLP and HHP allow for fast and safe maintenance due to an inspection cover.

The Self-Re-Priming pump type HLP and HHP allow for fast and safe maintenance due to an inspection cover.

To clean the pump just remove the inspection cover without removing any other pump parts or piping.

To clean the pump just remove the inspection cover without removing any other pump parts or piping.

To adjust the clearance between the impeller and the wear plate all you need is an Allen and a fixed wrench. No disassembly necessary...

To adjust the clearance between the impeller and the wear plate all you need is an Allen and a fixed wrench. No disassembly necessary...

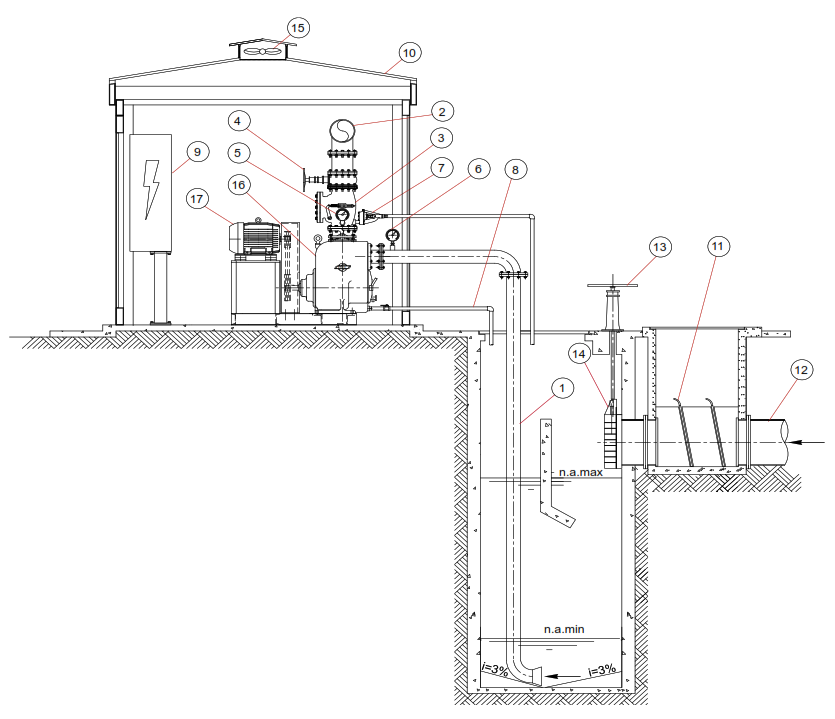

1. Suction Piping 2. Discharge Piping 3. Check Valve 4. Flexible Wedge Valve 5. Pressure Gauge 6. Pressure Gauge 7. Air Relief Valve 8. Drainpipe with Valve 9. Electric Panel10. Container11. Grading12. Sewage Main13. Sluice Gate Valve Pedestal 14. Sluice Gate Valve15. Fan16. Pump (HLP or HHP model) 17. Electric Motor

1. Suction Piping 2. Discharge Piping 3. Check Valve 4. Flexible Wedge Valve 5. Pressure Gauge 6. Pressure Gauge 7. Air Relief Valve 8. Drainpipe with Valve 9. Electric Panel10. Container11. Grading12. Sewage Main13. Sluice Gate Valve Pedestal 14. Sluice Gate Valve15. Fan16. Pump (HLP or HHP model) 17. Electric Motor

High and dry: Pump runs high and dry above the water level, so maintenance can be completed quickly and easily

Access: Ease of installation and maintenance

Wear Parts: Minimum number of wear parts

Foot valves: Not required

Air Handling: Automatically Self-Re-Primes following suction interruption

Back Pull Out: Easy maintenance or repair by removing a single-piece rotating assembly without disturbing any existing piping

Drive: Standard off-the-shelf motors

Impeller: Solid particles higher handling capabilities

Inspection Cover: No special tools are required to unclog the pump or replace the wear plate

Coupling: Direct or pulley and V-belt drive

Pump Out Vanes (impeller): Back of impeller prevent solid particles from building up in that region

Settled Solid Matter: Allows an odorless operation by reducing solid matters settling on the sump bottom

Heger Pumps, Inc. 24 h – hotline +1 (562) 989-5432 or info@hegerpumps.com